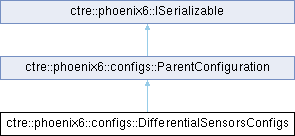

Configs related to sensors used for differential control of a mechanism. More...

#include <ctre/phoenix6/configs/DifferentialSensorsConfigs.hpp>

Public Member Functions | |

| constexpr | DifferentialSensorsConfigs ()=default |

| constexpr DifferentialSensorsConfigs & | WithDifferentialSensorSource (signals::DifferentialSensorSourceValue newDifferentialSensorSource) |

| Modifies this configuration's DifferentialSensorSource parameter and returns itself for method-chaining and easier to use config API. | |

| constexpr DifferentialSensorsConfigs & | WithDifferentialTalonFXSensorID (int newDifferentialTalonFXSensorID) |

| Modifies this configuration's DifferentialTalonFXSensorID parameter and returns itself for method-chaining and easier to use config API. | |

| constexpr DifferentialSensorsConfigs & | WithDifferentialRemoteSensorID (int newDifferentialRemoteSensorID) |

| Modifies this configuration's DifferentialRemoteSensorID parameter and returns itself for method-chaining and easier to use config API. | |

| constexpr DifferentialSensorsConfigs & | WithSensorToDifferentialRatio (units::dimensionless::scalar_t newSensorToDifferentialRatio) |

| Modifies this configuration's SensorToDifferentialRatio parameter and returns itself for method-chaining and easier to use config API. | |

| std::string | ToString () const override |

| std::string | Serialize () const final |

| ctre::phoenix::StatusCode | Deserialize (std::string const &to_deserialize) final |

Public Member Functions inherited from ctre::phoenix6::configs::ParentConfiguration Public Member Functions inherited from ctre::phoenix6::configs::ParentConfiguration | |

Public Member Functions inherited from ctre::phoenix6::ISerializable Public Member Functions inherited from ctre::phoenix6::ISerializable | |

Public Attributes | |

| signals::DifferentialSensorSourceValue | DifferentialSensorSource = signals::DifferentialSensorSourceValue::Disabled |

| Choose what sensor source is used for differential control of a mechanism. | |

| int | DifferentialTalonFXSensorID = 0 |

| Device ID of which remote Talon FX to use. | |

| int | DifferentialRemoteSensorID = 0 |

| Device ID of which remote sensor to use on the differential axis. | |

| units::dimensionless::scalar_t | SensorToDifferentialRatio = 1.0 |

| The ratio of sensor rotations to the differential mechanism's difference output, where a ratio greater than 1 is a reduction. | |

Detailed Description

Configs related to sensors used for differential control of a mechanism.

Includes the differential sensor sources and IDs.

Constructor & Destructor Documentation

◆ DifferentialSensorsConfigs()

|

constexprdefault |

Member Function Documentation

◆ Deserialize()

|

finalvirtual |

Implements ctre::phoenix6::configs::ParentConfiguration.

◆ Serialize()

|

finalvirtual |

Implements ctre::phoenix6::ISerializable.

◆ ToString()

|

overridevirtual |

Implements ctre::phoenix6::configs::ParentConfiguration.

◆ WithDifferentialRemoteSensorID()

|

inlineconstexpr |

Modifies this configuration's DifferentialRemoteSensorID parameter and returns itself for method-chaining and easier to use config API.

Device ID of which remote sensor to use on the differential axis. This is used when the Differential Sensor Source is not Disabled or RemoteTalonFX_HalfDiff.

- Minimum Value: 0

- Maximum Value: 62

- Default Value: 0

- Units:

- Parameters

-

newDifferentialRemoteSensorID Parameter to modify

- Returns

- Itself

◆ WithDifferentialSensorSource()

|

inlineconstexpr |

Modifies this configuration's DifferentialSensorSource parameter and returns itself for method-chaining and easier to use config API.

Choose what sensor source is used for differential control of a mechanism. The default is Disabled. All other options require setting the DifferentialTalonFXSensorID, as the average of this Talon FX's sensor and the remote TalonFX's sensor is used for the differential controller's primary targets.

Choose RemoteTalonFX_HalfDiff to use another TalonFX on the same CAN bus. Talon FX will update its differential position and velocity whenever the remote TalonFX publishes its information on CAN bus. The differential controller will use half of the difference between this TalonFX's sensor and the remote Talon FX's sensor for the differential component of the output.

Choose RemotePigeon2Yaw, RemotePigeon2Pitch, and RemotePigeon2Roll to use another Pigeon2 on the same CAN bus (this also requires setting DifferentialRemoteSensorID). Talon FX will update its differential position to match the selected value whenever Pigeon2 publishes its information on CAN bus. Note that the Talon FX differential position will be in rotations and not degrees.

Choose RemoteCANcoder to use another CANcoder on the same CAN bus (this also requires setting DifferentialRemoteSensorID). Talon FX will update its differential position and velocity to match the CANcoder whenever CANcoder publishes its information on CAN bus.

- Parameters

-

newDifferentialSensorSource Parameter to modify

- Returns

- Itself

◆ WithDifferentialTalonFXSensorID()

|

inlineconstexpr |

Modifies this configuration's DifferentialTalonFXSensorID parameter and returns itself for method-chaining and easier to use config API.

Device ID of which remote Talon FX to use. This is used whenever the Differential Sensor Source is not disabled.

The differential Talon FX must enable its Position and Velocity status signals. The update rate of the status signals determines the update rate of differential control.

- Minimum Value: 0

- Maximum Value: 62

- Default Value: 0

- Units:

- Parameters

-

newDifferentialTalonFXSensorID Parameter to modify

- Returns

- Itself

◆ WithSensorToDifferentialRatio()

|

inlineconstexpr |

Modifies this configuration's SensorToDifferentialRatio parameter and returns itself for method-chaining and easier to use config API.

The ratio of sensor rotations to the differential mechanism's difference output, where a ratio greater than 1 is a reduction.

When using RemoteTalonFX_HalfDiff, the sensor is considered half of the difference between the two devices' mechanism positions/velocities. As a result, this should be set to the gear ratio on the difference axis when using RemoteTalonFX_HalfDiff, or any gear ratio between the sensor and the mechanism differential when using another sensor source.

We recommend against using this config to perform onboard unit conversions. Instead, unit conversions should be performed in robot code using the units library.

If this is set to zero, the device will reset back to one.

- Minimum Value: -1000

- Maximum Value: 1000

- Default Value: 1.0

- Units: scalar

- Parameters

-

newSensorToDifferentialRatio Parameter to modify

- Returns

- Itself

Member Data Documentation

◆ DifferentialRemoteSensorID

| int ctre::phoenix6::configs::DifferentialSensorsConfigs::DifferentialRemoteSensorID = 0 |

Device ID of which remote sensor to use on the differential axis.

This is used when the Differential Sensor Source is not Disabled or RemoteTalonFX_HalfDiff.

- Minimum Value: 0

- Maximum Value: 62

- Default Value: 0

- Units:

◆ DifferentialSensorSource

| signals::DifferentialSensorSourceValue ctre::phoenix6::configs::DifferentialSensorsConfigs::DifferentialSensorSource = signals::DifferentialSensorSourceValue::Disabled |

Choose what sensor source is used for differential control of a mechanism.

The default is Disabled. All other options require setting the DifferentialTalonFXSensorID, as the average of this Talon FX's sensor and the remote TalonFX's sensor is used for the differential controller's primary targets.

Choose RemoteTalonFX_HalfDiff to use another TalonFX on the same CAN bus. Talon FX will update its differential position and velocity whenever the remote TalonFX publishes its information on CAN bus. The differential controller will use half of the difference between this TalonFX's sensor and the remote Talon FX's sensor for the differential component of the output.

Choose RemotePigeon2Yaw, RemotePigeon2Pitch, and RemotePigeon2Roll to use another Pigeon2 on the same CAN bus (this also requires setting DifferentialRemoteSensorID). Talon FX will update its differential position to match the selected value whenever Pigeon2 publishes its information on CAN bus. Note that the Talon FX differential position will be in rotations and not degrees.

Choose RemoteCANcoder to use another CANcoder on the same CAN bus (this also requires setting DifferentialRemoteSensorID). Talon FX will update its differential position and velocity to match the CANcoder whenever CANcoder publishes its information on CAN bus.

◆ DifferentialTalonFXSensorID

| int ctre::phoenix6::configs::DifferentialSensorsConfigs::DifferentialTalonFXSensorID = 0 |

Device ID of which remote Talon FX to use.

This is used whenever the Differential Sensor Source is not disabled.

The differential Talon FX must enable its Position and Velocity status signals. The update rate of the status signals determines the update rate of differential control.

- Minimum Value: 0

- Maximum Value: 62

- Default Value: 0

- Units:

◆ SensorToDifferentialRatio

| units::dimensionless::scalar_t ctre::phoenix6::configs::DifferentialSensorsConfigs::SensorToDifferentialRatio = 1.0 |

The ratio of sensor rotations to the differential mechanism's difference output, where a ratio greater than 1 is a reduction.

When using RemoteTalonFX_HalfDiff, the sensor is considered half of the difference between the two devices' mechanism positions/velocities. As a result, this should be set to the gear ratio on the difference axis when using RemoteTalonFX_HalfDiff, or any gear ratio between the sensor and the mechanism differential when using another sensor source.

We recommend against using this config to perform onboard unit conversions. Instead, unit conversions should be performed in robot code using the units library.

If this is set to zero, the device will reset back to one.

- Minimum Value: -1000

- Maximum Value: 1000

- Default Value: 1.0

- Units: scalar

The documentation for this class was generated from the following file:

- ctre/phoenix6/configs/DifferentialSensorsConfigs.hpp