Configs that affect the feedback of this motor controller. More...

#include <ctre/phoenix6/configs/FeedbackConfigs.hpp>

Public Member Functions | |

| constexpr | FeedbackConfigs ()=default |

| constexpr FeedbackConfigs & | WithFeedbackRotorOffset (units::angle::turn_t newFeedbackRotorOffset) |

| Modifies this configuration's FeedbackRotorOffset parameter and returns itself for method-chaining and easier to use config API. | |

| constexpr FeedbackConfigs & | WithSensorToMechanismRatio (units::dimensionless::scalar_t newSensorToMechanismRatio) |

| Modifies this configuration's SensorToMechanismRatio parameter and returns itself for method-chaining and easier to use config API. | |

| constexpr FeedbackConfigs & | WithRotorToSensorRatio (units::dimensionless::scalar_t newRotorToSensorRatio) |

| Modifies this configuration's RotorToSensorRatio parameter and returns itself for method-chaining and easier to use config API. | |

| constexpr FeedbackConfigs & | WithFeedbackSensorSource (signals::FeedbackSensorSourceValue newFeedbackSensorSource) |

| Modifies this configuration's FeedbackSensorSource parameter and returns itself for method-chaining and easier to use config API. | |

| constexpr FeedbackConfigs & | WithFeedbackRemoteSensorID (int newFeedbackRemoteSensorID) |

| Modifies this configuration's FeedbackRemoteSensorID parameter and returns itself for method-chaining and easier to use config API. | |

| constexpr FeedbackConfigs & | WithVelocityFilterTimeConstant (units::time::second_t newVelocityFilterTimeConstant) |

| Modifies this configuration's VelocityFilterTimeConstant parameter and returns itself for method-chaining and easier to use config API. | |

| FeedbackConfigs & | WithRemoteCANcoder (const hardware::core::CoreCANcoder &device) |

| Helper method to configure this feedback group to use RemoteCANcoder by passing in the CANcoder object. | |

| FeedbackConfigs & | WithFusedCANcoder (const hardware::core::CoreCANcoder &device) |

| Helper method to configure this feedback group to use FusedCANcoder by passing in the CANcoder object. | |

| FeedbackConfigs & | WithSyncCANcoder (const hardware::core::CoreCANcoder &device) |

| Helper method to configure this feedback group to use SyncCANcoder by passing in the CANcoder object. | |

| FeedbackConfigs & | WithRemotePigeon2Yaw (const hardware::core::CorePigeon2 &device) |

| Helper method to configure this feedback group to use RemotePigeon2Yaw by passing in the Pigeon2 object. | |

| FeedbackConfigs & | WithRemotePigeon2Pitch (const hardware::core::CorePigeon2 &device) |

| Helper method to configure this feedback group to use RemotePigeon2Pitch by passing in the Pigeon2 object. | |

| FeedbackConfigs & | WithRemotePigeon2Roll (const hardware::core::CorePigeon2 &device) |

| Helper method to configure this feedback group to use RemotePigeon2Roll by passing in the Pigeon2 object. | |

| FeedbackConfigs & | WithRemoteCANdiPWM1 (const hardware::core::CoreCANdi &device) |

| Helper method to configure this feedback group to use RemoteCANdi PWM 1 by passing in the CANdi object. | |

| FeedbackConfigs & | WithRemoteCANdiPWM2 (const hardware::core::CoreCANdi &device) |

| Helper method to configure this feedback group to use RemoteCANdi PWM 2 by passing in the CANdi object. | |

| FeedbackConfigs & | WithRemoteCANdiQuadrature (const hardware::core::CoreCANdi &device) |

| Helper method to configure this feedback group to use RemoteCANdi Quadrature by passing in the CANdi object. | |

| FeedbackConfigs & | WithFusedCANdiPWM1 (const hardware::core::CoreCANdi &device) |

| Helper method to configure this feedback group to use FusedCANdi PWM 1 by passing in the CANdi object. | |

| FeedbackConfigs & | WithFusedCANdiPWM2 (const hardware::core::CoreCANdi &device) |

| Helper method to configure this feedback group to use FusedCANdi PWM 2 by passing in the CANdi object. | |

| FeedbackConfigs & | WithFusedCANdiQuadrature (const hardware::core::CoreCANdi &device) |

| Helper method to configure this feedback group to use FusedCANdi Quadrature by passing in the CANdi object. | |

| FeedbackConfigs & | WithSyncCANdiPWM1 (const hardware::core::CoreCANdi &device) |

| Helper method to configure this feedback group to use SyncCANdi PWM 1 by passing in the CANdi object. | |

| FeedbackConfigs & | WithSyncCANdiPWM2 (const hardware::core::CoreCANdi &device) |

| Helper method to configure this feedback group to use SyncCANdi PWM 2 by passing in the CANdi object. | |

| std::string | ToString () const override |

| std::string | Serialize () const final |

| ctre::phoenix::StatusCode | Deserialize (std::string const &to_deserialize) final |

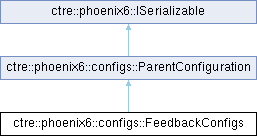

Public Member Functions inherited from ctre::phoenix6::configs::ParentConfiguration Public Member Functions inherited from ctre::phoenix6::configs::ParentConfiguration | |

Public Member Functions inherited from ctre::phoenix6::ISerializable Public Member Functions inherited from ctre::phoenix6::ISerializable | |

Public Attributes | |

| units::angle::turn_t | FeedbackRotorOffset = 0.0_tr |

| The offset added to the absolute integrated rotor sensor. | |

| units::dimensionless::scalar_t | SensorToMechanismRatio = 1.0 |

| The ratio of sensor rotations to the mechanism's output, where a ratio greater than 1 is a reduction. | |

| units::dimensionless::scalar_t | RotorToSensorRatio = 1.0 |

| The ratio of motor rotor rotations to remote sensor rotations, where a ratio greater than 1 is a reduction. | |

| signals::FeedbackSensorSourceValue | FeedbackSensorSource = signals::FeedbackSensorSourceValue::RotorSensor |

| Choose what sensor source is reported via API and used by closed-loop and limit features. | |

| int | FeedbackRemoteSensorID = 0 |

| Device ID of which remote device to use. | |

| units::time::second_t | VelocityFilterTimeConstant = 0_s |

| The configurable time constant of the Kalman velocity filter. | |

Detailed Description

Configs that affect the feedback of this motor controller.

Includes feedback sensor source, any offsets for the feedback sensor, and various ratios to describe the relationship between the sensor and the mechanism for closed looping.

Constructor & Destructor Documentation

◆ FeedbackConfigs()

|

constexprdefault |

Member Function Documentation

◆ Deserialize()

|

finalvirtual |

Implements ctre::phoenix6::configs::ParentConfiguration.

◆ Serialize()

|

finalvirtual |

Implements ctre::phoenix6::ISerializable.

◆ ToString()

|

overridevirtual |

Implements ctre::phoenix6::configs::ParentConfiguration.

◆ WithFeedbackRemoteSensorID()

|

inlineconstexpr |

Modifies this configuration's FeedbackRemoteSensorID parameter and returns itself for method-chaining and easier to use config API.

Device ID of which remote device to use. This is not used if the Sensor Source is the internal rotor sensor.

- Minimum Value: 0

- Maximum Value: 62

- Default Value: 0

- Units:

- Parameters

-

newFeedbackRemoteSensorID Parameter to modify

- Returns

- Itself

◆ WithFeedbackRotorOffset()

|

inlineconstexpr |

Modifies this configuration's FeedbackRotorOffset parameter and returns itself for method-chaining and easier to use config API.

The offset added to the absolute integrated rotor sensor. This can be used to zero the rotor in applications that are within one rotor rotation.

- Minimum Value: -1

- Maximum Value: 1

- Default Value: 0.0

- Units: rotations

- Parameters

-

newFeedbackRotorOffset Parameter to modify

- Returns

- Itself

◆ WithFeedbackSensorSource()

|

inlineconstexpr |

Modifies this configuration's FeedbackSensorSource parameter and returns itself for method-chaining and easier to use config API.

Choose what sensor source is reported via API and used by closed-loop and limit features. The default is RotorSensor, which uses the internal rotor sensor in the Talon.

Choose Remote* to use another sensor on the same CAN bus (this also requires setting FeedbackRemoteSensorID). Talon will update its position and velocity whenever the remote sensor publishes its information on CAN bus, and the Talon internal rotor will not be used.

Choose Fused* (requires Phoenix Pro) and Talon will fuse another sensor's information with the internal rotor, which provides the best possible position and velocity for accuracy and bandwidth (this also requires setting FeedbackRemoteSensorID). This was developed for applications such as swerve-azimuth.

Choose Sync* (requires Phoenix Pro) and Talon will synchronize its internal rotor position against another sensor, then continue to use the rotor sensor for closed loop control (this also requires setting FeedbackRemoteSensorID). The Talon will report if its internal position differs significantly from the reported remote sensor position. This was developed for mechanisms where there is a risk of the sensor failing in such a way that it reports a position that does not match the mechanism, such as the sensor mounting assembly breaking off.

Choose RemotePigeon2Yaw, RemotePigeon2Pitch, and RemotePigeon2Roll to use another Pigeon2 on the same CAN bus (this also requires setting FeedbackRemoteSensorID). Talon will update its position to match the selected value whenever Pigeon2 publishes its information on CAN bus. Note that the Talon position will be in rotations and not degrees.

Note: When the feedback source is changed to Fused* or Sync*, the Talon needs a period of time to fuse before sensor-based (soft-limit, closed loop, etc.) features are used. This period of time is determined by the update frequency of the remote sensor's Position signal.

- Parameters

-

newFeedbackSensorSource Parameter to modify

- Returns

- Itself

◆ WithFusedCANcoder()

| FeedbackConfigs & ctre::phoenix6::configs::FeedbackConfigs::WithFusedCANcoder | ( | const hardware::core::CoreCANcoder & | device | ) |

Helper method to configure this feedback group to use FusedCANcoder by passing in the CANcoder object.

When using FusedCANcoder (requires Phoenix Pro), the Talon will fuse another CANcoder's information with the internal rotor, which provides the best possible position and velocity for accuracy and bandwidth. FusedCANcoder was developed for applications such as swerve-azimuth.

- Parameters

-

device CANcoder reference to use for FusedCANcoder

- Returns

- Itself

◆ WithFusedCANdiPWM1()

| FeedbackConfigs & ctre::phoenix6::configs::FeedbackConfigs::WithFusedCANdiPWM1 | ( | const hardware::core::CoreCANdi & | device | ) |

Helper method to configure this feedback group to use FusedCANdi PWM 1 by passing in the CANdi object.

When using FusedCANdi (requires Phoenix Pro), the Talon will fuse another CANdi™ branded device's information with the internal rotor, which provides the best possible position and velocity for accuracy and bandwidth.

- Parameters

-

device CANdi reference to use for FusedCANdi

- Returns

- Itself

◆ WithFusedCANdiPWM2()

| FeedbackConfigs & ctre::phoenix6::configs::FeedbackConfigs::WithFusedCANdiPWM2 | ( | const hardware::core::CoreCANdi & | device | ) |

Helper method to configure this feedback group to use FusedCANdi PWM 2 by passing in the CANdi object.

When using FusedCANdi (requires Phoenix Pro), the Talon will fuse another CANdi™ branded device's information with the internal rotor, which provides the best possible position and velocity for accuracy and bandwidth.

- Parameters

-

device CANdi reference to use for FusedCANdi

- Returns

- Itself

◆ WithFusedCANdiQuadrature()

| FeedbackConfigs & ctre::phoenix6::configs::FeedbackConfigs::WithFusedCANdiQuadrature | ( | const hardware::core::CoreCANdi & | device | ) |

Helper method to configure this feedback group to use FusedCANdi Quadrature by passing in the CANdi object.

When using FusedCANdi (requires Phoenix Pro), the Talon will fuse another CANdi™ branded device's information with the internal rotor, which provides the best possible position and velocity for accuracy and bandwidth.

- Parameters

-

device CANdi reference to use for FusedCANdi

- Returns

- Itself

◆ WithRemoteCANcoder()

| FeedbackConfigs & ctre::phoenix6::configs::FeedbackConfigs::WithRemoteCANcoder | ( | const hardware::core::CoreCANcoder & | device | ) |

Helper method to configure this feedback group to use RemoteCANcoder by passing in the CANcoder object.

When using RemoteCANcoder, the Talon will use another CANcoder on the same CAN bus. The Talon will update its position and velocity whenever CANcoder publishes its information on CAN bus, and the Talon internal rotor will not be used.

- Parameters

-

device CANcoder reference to use for RemoteCANcoder

- Returns

- Itself

◆ WithRemoteCANdiPWM1()

| FeedbackConfigs & ctre::phoenix6::configs::FeedbackConfigs::WithRemoteCANdiPWM1 | ( | const hardware::core::CoreCANdi & | device | ) |

Helper method to configure this feedback group to use RemoteCANdi PWM 1 by passing in the CANdi object.

When using RemoteCANdi, the Talon will use another CTR Electronics' CANdi™ on the same CAN bus. The Talon will update its position and velocity whenever the CTR Electronics' CANdi™ publishes its information on CAN bus, and the Talon commutation sensor will not be used.

- Parameters

-

device CANdi reference to use for RemoteCANdi

- Returns

- Itself

◆ WithRemoteCANdiPWM2()

| FeedbackConfigs & ctre::phoenix6::configs::FeedbackConfigs::WithRemoteCANdiPWM2 | ( | const hardware::core::CoreCANdi & | device | ) |

Helper method to configure this feedback group to use RemoteCANdi PWM 2 by passing in the CANdi object.

When using RemoteCANdi, the Talon will use another CTR Electronics' CANdi™ on the same CAN bus. The Talon will update its position and velocity whenever the CTR Electronics' CANdi™ publishes its information on CAN bus, and the Talon commutation sensor will not be used.

- Parameters

-

device CANdi reference to use for RemoteCANdi

- Returns

- Itself

◆ WithRemoteCANdiQuadrature()

| FeedbackConfigs & ctre::phoenix6::configs::FeedbackConfigs::WithRemoteCANdiQuadrature | ( | const hardware::core::CoreCANdi & | device | ) |

Helper method to configure this feedback group to use RemoteCANdi Quadrature by passing in the CANdi object.

When using RemoteCANdi, the Talon will use another CTR Electronics' CANdi™ on the same CAN bus. The Talon will update its position and velocity whenever the CTR Electronics' CANdi™ publishes its information on CAN bus, and the Talon commutation sensor will not be used.

- Parameters

-

device CANdi reference to use for RemoteCANdi

- Returns

- Itself

◆ WithRemotePigeon2Pitch()

| FeedbackConfigs & ctre::phoenix6::configs::FeedbackConfigs::WithRemotePigeon2Pitch | ( | const hardware::core::CorePigeon2 & | device | ) |

Helper method to configure this feedback group to use RemotePigeon2Pitch by passing in the Pigeon2 object.

When using RemotePigeon2Pitch, the Talon will use another Pigeon2 on the same CAN bus. The Talon will update its position to match the Pigeon2 pitch whenever Pigeon2 publishes its information on CAN bus. Note that the Talon position will be in rotations and not degrees.

- Parameters

-

device Pigeon2 reference to use for RemotePigeon2Pitch

- Returns

- Itself

◆ WithRemotePigeon2Roll()

| FeedbackConfigs & ctre::phoenix6::configs::FeedbackConfigs::WithRemotePigeon2Roll | ( | const hardware::core::CorePigeon2 & | device | ) |

Helper method to configure this feedback group to use RemotePigeon2Roll by passing in the Pigeon2 object.

When using RemotePigeon2Roll, the Talon will use another Pigeon2 on the same CAN bus. The Talon will update its position to match the Pigeon2 roll whenever Pigeon2 publishes its information on CAN bus. Note that the Talon position will be in rotations and not degrees.

- Parameters

-

device Pigeon2 reference to use for RemotePigeon2Roll

- Returns

- Itself

◆ WithRemotePigeon2Yaw()

| FeedbackConfigs & ctre::phoenix6::configs::FeedbackConfigs::WithRemotePigeon2Yaw | ( | const hardware::core::CorePigeon2 & | device | ) |

Helper method to configure this feedback group to use RemotePigeon2Yaw by passing in the Pigeon2 object.

When using RemotePigeon2Yaw, the Talon will use another Pigeon2 on the same CAN bus. The Talon will update its position to match the Pigeon2 yaw whenever Pigeon2 publishes its information on CAN bus. Note that the Talon position will be in rotations and not degrees.

- Parameters

-

device Pigeon2 reference to use for RemotePigeon2Yaw

- Returns

- Itself

◆ WithRotorToSensorRatio()

|

inlineconstexpr |

Modifies this configuration's RotorToSensorRatio parameter and returns itself for method-chaining and easier to use config API.

The ratio of motor rotor rotations to remote sensor rotations, where a ratio greater than 1 is a reduction.

The Talon FX is capable of fusing a remote CANcoder with its rotor sensor to produce a high-bandwidth sensor source. This feature requires specifying the ratio between the motor rotor and the remote sensor.

If this is set to zero, the device will reset back to one.

- Minimum Value: -1000

- Maximum Value: 1000

- Default Value: 1.0

- Units: scalar

- Parameters

-

newRotorToSensorRatio Parameter to modify

- Returns

- Itself

◆ WithSensorToMechanismRatio()

|

inlineconstexpr |

Modifies this configuration's SensorToMechanismRatio parameter and returns itself for method-chaining and easier to use config API.

The ratio of sensor rotations to the mechanism's output, where a ratio greater than 1 is a reduction.

This is equivalent to the mechanism's gear ratio if the sensor is located on the input of a gearbox. If sensor is on the output of a gearbox, then this is typically set to 1.

We recommend against using this config to perform onboard unit conversions. Instead, unit conversions should be performed in robot code using the units library.

If this is set to zero, the device will reset back to one.

- Minimum Value: -1000

- Maximum Value: 1000

- Default Value: 1.0

- Units: scalar

- Parameters

-

newSensorToMechanismRatio Parameter to modify

- Returns

- Itself

◆ WithSyncCANcoder()

| FeedbackConfigs & ctre::phoenix6::configs::FeedbackConfigs::WithSyncCANcoder | ( | const hardware::core::CoreCANcoder & | device | ) |

Helper method to configure this feedback group to use SyncCANcoder by passing in the CANcoder object.

When using SyncCANcoder (requires Phoenix Pro), the Talon will synchronize its internal rotor position against another CANcoder, then continue to use the rotor sensor for closed loop control. The Talon will report if its internal position differs significantly from the reported CANcoder position. SyncCANcoder was developed for mechanisms where there is a risk of the CANcoder failing in such a way that it reports a position that does not match the mechanism, such as the sensor mounting assembly breaking off.

- Parameters

-

device CANcoder reference to use for SyncCANcoder

- Returns

- Itself

◆ WithSyncCANdiPWM1()

| FeedbackConfigs & ctre::phoenix6::configs::FeedbackConfigs::WithSyncCANdiPWM1 | ( | const hardware::core::CoreCANdi & | device | ) |

Helper method to configure this feedback group to use SyncCANdi PWM 1 by passing in the CANdi object.

When using SyncCANdi (requires Phoenix Pro), the Talon will synchronize its internal rotor position against another CANdi™ branded device, then continue to use the rotor sensor for closed loop control. The Talon will report if its internal position differs significantly from the reported CANdi™ branded device's position. SyncCANdi was developed for mechanisms where there is a risk of the CANdi™ branded device failing in such a way that it reports a position that does not match the mechanism, such as the sensor mounting assembly breaking off.

- Parameters

-

device CANdi reference to use for SyncCANdi

- Returns

- Itself

◆ WithSyncCANdiPWM2()

| FeedbackConfigs & ctre::phoenix6::configs::FeedbackConfigs::WithSyncCANdiPWM2 | ( | const hardware::core::CoreCANdi & | device | ) |

Helper method to configure this feedback group to use SyncCANdi PWM 2 by passing in the CANdi object.

When using SyncCANdi (requires Phoenix Pro), the Talon will synchronize its internal rotor position against another CANdi™ branded device, then continue to use the rotor sensor for closed loop control. The Talon will report if its internal position differs significantly from the reported CANdi™ branded device's position. SyncCANdi was developed for mechanisms where there is a risk of the CANdi™ branded device failing in such a way that it reports a position that does not match the mechanism, such as the sensor mounting assembly breaking off.

- Parameters

-

device CANdi reference to use for SyncCANdi

- Returns

- Itself

◆ WithVelocityFilterTimeConstant()

|

inlineconstexpr |

Modifies this configuration's VelocityFilterTimeConstant parameter and returns itself for method-chaining and easier to use config API.

The configurable time constant of the Kalman velocity filter. The velocity Kalman filter will adjust to act as a low-pass with this value as its time constant.

If the user is aiming for an expected cutoff frequency, the frequency is calculated as 1 / (2 * π * τ) with τ being the time constant.

- Minimum Value: 0

- Maximum Value: 1

- Default Value: 0

- Units: seconds

- Parameters

-

newVelocityFilterTimeConstant Parameter to modify

- Returns

- Itself

Member Data Documentation

◆ FeedbackRemoteSensorID

| int ctre::phoenix6::configs::FeedbackConfigs::FeedbackRemoteSensorID = 0 |

Device ID of which remote device to use.

This is not used if the Sensor Source is the internal rotor sensor.

- Minimum Value: 0

- Maximum Value: 62

- Default Value: 0

- Units:

◆ FeedbackRotorOffset

| units::angle::turn_t ctre::phoenix6::configs::FeedbackConfigs::FeedbackRotorOffset = 0.0_tr |

The offset added to the absolute integrated rotor sensor.

This can be used to zero the rotor in applications that are within one rotor rotation.

- Minimum Value: -1

- Maximum Value: 1

- Default Value: 0.0

- Units: rotations

◆ FeedbackSensorSource

| signals::FeedbackSensorSourceValue ctre::phoenix6::configs::FeedbackConfigs::FeedbackSensorSource = signals::FeedbackSensorSourceValue::RotorSensor |

Choose what sensor source is reported via API and used by closed-loop and limit features.

The default is RotorSensor, which uses the internal rotor sensor in the Talon.

Choose Remote* to use another sensor on the same CAN bus (this also requires setting FeedbackRemoteSensorID). Talon will update its position and velocity whenever the remote sensor publishes its information on CAN bus, and the Talon internal rotor will not be used.

Choose Fused* (requires Phoenix Pro) and Talon will fuse another sensor's information with the internal rotor, which provides the best possible position and velocity for accuracy and bandwidth (this also requires setting FeedbackRemoteSensorID). This was developed for applications such as swerve-azimuth.

Choose Sync* (requires Phoenix Pro) and Talon will synchronize its internal rotor position against another sensor, then continue to use the rotor sensor for closed loop control (this also requires setting FeedbackRemoteSensorID). The Talon will report if its internal position differs significantly from the reported remote sensor position. This was developed for mechanisms where there is a risk of the sensor failing in such a way that it reports a position that does not match the mechanism, such as the sensor mounting assembly breaking off.

Choose RemotePigeon2Yaw, RemotePigeon2Pitch, and RemotePigeon2Roll to use another Pigeon2 on the same CAN bus (this also requires setting FeedbackRemoteSensorID). Talon will update its position to match the selected value whenever Pigeon2 publishes its information on CAN bus. Note that the Talon position will be in rotations and not degrees.

Note: When the feedback source is changed to Fused* or Sync*, the Talon needs a period of time to fuse before sensor-based (soft-limit, closed loop, etc.) features are used. This period of time is determined by the update frequency of the remote sensor's Position signal.

◆ RotorToSensorRatio

| units::dimensionless::scalar_t ctre::phoenix6::configs::FeedbackConfigs::RotorToSensorRatio = 1.0 |

The ratio of motor rotor rotations to remote sensor rotations, where a ratio greater than 1 is a reduction.

The Talon FX is capable of fusing a remote CANcoder with its rotor sensor to produce a high-bandwidth sensor source. This feature requires specifying the ratio between the motor rotor and the remote sensor.

If this is set to zero, the device will reset back to one.

- Minimum Value: -1000

- Maximum Value: 1000

- Default Value: 1.0

- Units: scalar

◆ SensorToMechanismRatio

| units::dimensionless::scalar_t ctre::phoenix6::configs::FeedbackConfigs::SensorToMechanismRatio = 1.0 |

The ratio of sensor rotations to the mechanism's output, where a ratio greater than 1 is a reduction.

This is equivalent to the mechanism's gear ratio if the sensor is located on the input of a gearbox. If sensor is on the output of a gearbox, then this is typically set to 1.

We recommend against using this config to perform onboard unit conversions. Instead, unit conversions should be performed in robot code using the units library.

If this is set to zero, the device will reset back to one.

- Minimum Value: -1000

- Maximum Value: 1000

- Default Value: 1.0

- Units: scalar

◆ VelocityFilterTimeConstant

| units::time::second_t ctre::phoenix6::configs::FeedbackConfigs::VelocityFilterTimeConstant = 0_s |

The configurable time constant of the Kalman velocity filter.

The velocity Kalman filter will adjust to act as a low-pass with this value as its time constant.

If the user is aiming for an expected cutoff frequency, the frequency is calculated as 1 / (2 * π * τ) with τ being the time constant.

- Minimum Value: 0

- Maximum Value: 1

- Default Value: 0

- Units: seconds

The documentation for this class was generated from the following file:

- ctre/phoenix6/configs/FeedbackConfigs.hpp