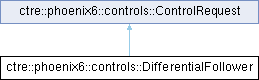

Follow the differential motor output of another Talon. More...

#include <ctre/phoenix6/controls/DifferentialFollower.hpp>

Public Member Functions | |

| constexpr | DifferentialFollower (int LeaderID, signals::MotorAlignmentValue MotorAlignment) |

| Follow the differential motor output of another Talon. | |

| constexpr | ~DifferentialFollower () override |

| constexpr std::string_view | GetName () const override |

| Gets the name of this control request. | |

| constexpr DifferentialFollower & | WithLeaderID (int newLeaderID) |

| Modifies this Control Request's LeaderID parameter and returns itself for method-chaining and easier to use request API. | |

| constexpr DifferentialFollower & | WithMotorAlignment (signals::MotorAlignmentValue newMotorAlignment) |

| Modifies this Control Request's MotorAlignment parameter and returns itself for method-chaining and easier to use request API. | |

| constexpr DifferentialFollower & | WithUpdateFreqHz (units::frequency::hertz_t newUpdateFreqHz) |

| Sets the frequency at which this control will update. | |

| std::string | ToString () const override |

| Returns a string representation of the object. | |

| std::map< std::string, std::string > | GetControlInfo () const override |

| Gets information about this control request. | |

Public Member Functions inherited from ctre::phoenix6::controls::ControlRequest Public Member Functions inherited from ctre::phoenix6::controls::ControlRequest | |

| constexpr | ControlRequest ()=default |

| Constructs a new Control Request. | |

| virtual constexpr | ~ControlRequest () |

Public Attributes | |

| int | LeaderID |

| Device ID of the differential leader to follow. | |

| signals::MotorAlignmentValue | MotorAlignment |

| Set to Aligned for motor invert to match the leader's configured Invert - which is typical when leader and follower are mechanically linked and spin in the same direction. | |

| units::frequency::hertz_t | UpdateFreqHz {20_Hz} |

| The frequency at which this control will update. | |

Additional Inherited Members | |

Protected Member Functions inherited from ctre::phoenix6::controls::ControlRequest Protected Member Functions inherited from ctre::phoenix6::controls::ControlRequest | |

| constexpr | ControlRequest (ControlRequest const &)=default |

| constexpr | ControlRequest (ControlRequest &&)=default |

| constexpr ControlRequest & | operator= (ControlRequest const &)=default |

| constexpr ControlRequest & | operator= (ControlRequest &&)=default |

Detailed Description

Follow the differential motor output of another Talon.

If Talon is in torque control, the differential torque is copied - which will increase the total torque applied. If Talon is in duty cycle output control, the differential duty cycle is matched. If Talon is in voltage output control, the differential motor voltage is matched. Motor direction either matches leader's configured direction or opposes it based on the MotorAlignment.

The leader must enable its DifferentialOutput status signal. The update rate of the status signal determines the update rate of the follower's output and should be no slower than 20 Hz.

Constructor & Destructor Documentation

◆ DifferentialFollower()

|

inlineconstexpr |

Follow the differential motor output of another Talon.

If Talon is in torque control, the differential torque is copied - which will increase the total torque applied. If Talon is in duty cycle output control, the differential duty cycle is matched. If Talon is in voltage output control, the differential motor voltage is matched. Motor direction either matches leader's configured direction or opposes it based on the MotorAlignment.

The leader must enable its DifferentialOutput status signal. The update rate of the status signal determines the update rate of the follower's output and should be no slower than 20 Hz.

- Parameters

-

LeaderID Device ID of the differential leader to follow. MotorAlignment Set to Aligned for motor invert to match the leader's configured Invert - which is typical when leader and follower are mechanically linked and spin in the same direction. Set to Opposed for motor invert to oppose the leader's configured Invert - this is typical where the leader and follower mechanically spin in opposite directions.

◆ ~DifferentialFollower()

|

inlineconstexproverride |

Member Function Documentation

◆ GetControlInfo()

|

overridevirtual |

Gets information about this control request.

- Returns

- Map of control parameter names and corresponding applied values

Implements ctre::phoenix6::controls::ControlRequest.

◆ GetName()

|

inlineconstexproverridevirtual |

Gets the name of this control request.

- Returns

- Name of the control request

Implements ctre::phoenix6::controls::ControlRequest.

◆ ToString()

|

overridevirtual |

Returns a string representation of the object.

- Returns

- a string representation of the object.

Implements ctre::phoenix6::controls::ControlRequest.

◆ WithLeaderID()

|

inlineconstexpr |

Modifies this Control Request's LeaderID parameter and returns itself for method-chaining and easier to use request API.

Device ID of the differential leader to follow.

- Parameters

-

newLeaderID Parameter to modify

- Returns

- Itself

◆ WithMotorAlignment()

|

inlineconstexpr |

Modifies this Control Request's MotorAlignment parameter and returns itself for method-chaining and easier to use request API.

Set to Aligned for motor invert to match the leader's configured Invert - which is typical when leader and follower are mechanically linked and spin in the same direction. Set to Opposed for motor invert to oppose the leader's configured Invert - this is typical where the leader and follower mechanically spin in opposite directions.

- Parameters

-

newMotorAlignment Parameter to modify

- Returns

- Itself

◆ WithUpdateFreqHz()

|

inlineconstexpr |

Sets the frequency at which this control will update.

This is designated in Hertz, with a minimum of 20 Hz (every 50 ms) and a maximum of 1000 Hz (every 1 ms). Some update frequencies are not supported and will be promoted up to the next highest supported frequency.

If this field is set to 0 Hz, the control request will be sent immediately as a one-shot frame. This may be useful for advanced applications that require outputs to be synchronized with data acquisition. In this case, we recommend not exceeding 50 ms between control calls.

- Parameters

-

newUpdateFreqHz Parameter to modify

- Returns

- Itself

Member Data Documentation

◆ LeaderID

| int ctre::phoenix6::controls::DifferentialFollower::LeaderID |

Device ID of the differential leader to follow.

◆ MotorAlignment

| signals::MotorAlignmentValue ctre::phoenix6::controls::DifferentialFollower::MotorAlignment |

Set to Aligned for motor invert to match the leader's configured Invert - which is typical when leader and follower are mechanically linked and spin in the same direction.

Set to Opposed for motor invert to oppose the leader's configured Invert - this is typical where the leader and follower mechanically spin in opposite directions.

◆ UpdateFreqHz

| units::frequency::hertz_t ctre::phoenix6::controls::DifferentialFollower::UpdateFreqHz {20_Hz} |

The frequency at which this control will update.

This is designated in Hertz, with a minimum of 20 Hz (every 50 ms) and a maximum of 1000 Hz (every 1 ms). Some update frequencies are not supported and will be promoted up to the next highest supported frequency.

If this field is set to 0 Hz, the control request will be sent immediately as a one-shot frame. This may be useful for advanced applications that require outputs to be synchronized with data acquisition. In this case, we recommend not exceeding 50 ms between control calls.

The documentation for this class was generated from the following file:

- ctre/phoenix6/controls/DifferentialFollower.hpp