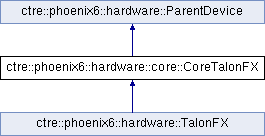

Class description for the Talon FX integrated motor controller. More...

#include <ctre/phoenix6/core/CoreTalonFX.hpp>

Public Types | |

| using | Configuration = configs::TalonFXConfiguration |

Public Member Functions | |

| CoreTalonFX (int deviceId, std::string canbus="") | |

| Constructs a new Talon FX motor controller object. | |

| CoreTalonFX (int deviceId, CANBus canbus) | |

| Constructs a new Talon FX motor controller object. | |

| configs::TalonFXConfigurator & | GetConfigurator () |

| Gets the configurator for this TalonFX. | |

| configs::TalonFXConfigurator const & | GetConfigurator () const |

| Gets the configurator for this TalonFX. | |

| sim::TalonFXSimState & | GetSimState () |

| Get the simulation state for this device. | |

| StatusSignal< int > & | GetVersionMajor (bool refresh=true) override |

| App Major Version number. | |

| StatusSignal< int > & | GetVersionMinor (bool refresh=true) override |

| App Minor Version number. | |

| StatusSignal< int > & | GetVersionBugfix (bool refresh=true) override |

| App Bugfix Version number. | |

| StatusSignal< int > & | GetVersionBuild (bool refresh=true) override |

| App Build Version number. | |

| StatusSignal< int > & | GetVersion (bool refresh=true) override |

| Full Version of firmware in device. | |

| StatusSignal< int > & | GetFaultField (bool refresh=true) override |

| Integer representing all fault flags reported by the device. | |

| StatusSignal< int > & | GetStickyFaultField (bool refresh=true) override |

| Integer representing all (persistent) sticky fault flags reported by the device. | |

| StatusSignal< units::voltage::volt_t > & | GetMotorVoltage (bool refresh=true) override |

| The applied (output) motor voltage. | |

| StatusSignal< signals::ForwardLimitValue > & | GetForwardLimit (bool refresh=true) override |

| Forward Limit Pin. | |

| StatusSignal< signals::ReverseLimitValue > & | GetReverseLimit (bool refresh=true) override |

| Reverse Limit Pin. | |

| StatusSignal< signals::AppliedRotorPolarityValue > & | GetAppliedRotorPolarity (bool refresh=true) override |

| The applied rotor polarity as seen from the front of the motor. | |

| StatusSignal< units::dimensionless::scalar_t > & | GetDutyCycle (bool refresh=true) override |

| The applied motor duty cycle. | |

| StatusSignal< units::current::ampere_t > & | GetTorqueCurrent (bool refresh=true) override |

| Current corresponding to the torque output by the motor. | |

| StatusSignal< units::current::ampere_t > & | GetStatorCurrent (bool refresh=true) override |

| Current corresponding to the stator windings. | |

| StatusSignal< units::current::ampere_t > & | GetSupplyCurrent (bool refresh=true) override |

| Measured supply side current. | |

| StatusSignal< units::voltage::volt_t > & | GetSupplyVoltage (bool refresh=true) override |

| Measured supply voltage to the device. | |

| StatusSignal< units::temperature::celsius_t > & | GetDeviceTemp (bool refresh=true) override |

| Temperature of device. | |

| StatusSignal< units::temperature::celsius_t > & | GetProcessorTemp (bool refresh=true) override |

| Temperature of the processor. | |

| StatusSignal< units::angular_velocity::turns_per_second_t > & | GetRotorVelocity (bool refresh=true) override |

| Velocity of the motor rotor. | |

| StatusSignal< units::angle::turn_t > & | GetRotorPosition (bool refresh=true) override |

| Position of the motor rotor. | |

| StatusSignal< units::angular_velocity::turns_per_second_t > & | GetVelocity (bool refresh=true) override |

| Velocity of the device in mechanism rotations per second. | |

| StatusSignal< units::angle::turn_t > & | GetPosition (bool refresh=true) override |

| Position of the device in mechanism rotations. | |

| StatusSignal< units::angular_acceleration::turns_per_second_squared_t > & | GetAcceleration (bool refresh=true) override |

| Acceleration of the device in mechanism rotations per second². | |

| StatusSignal< signals::ControlModeValue > & | GetControlMode (bool refresh=true) override |

| The active control mode of the motor controller. | |

| StatusSignal< signals::MotionMagicIsRunningValue > & | GetMotionMagicIsRunning (bool refresh=true) override |

| Check if Motion Magic® is running. | |

| StatusSignal< signals::RobotEnableValue > & | GetRobotEnable (bool refresh=true) override |

| Indicates if the robot is enabled. | |

| StatusSignal< signals::DeviceEnableValue > & | GetDeviceEnable (bool refresh=true) override |

| Indicates if device is actuator enabled. | |

| StatusSignal< int > & | GetClosedLoopSlot (bool refresh=true) override |

| The slot that the closed-loop PID is using. | |

| StatusSignal< signals::MotorOutputStatusValue > & | GetMotorOutputStatus (bool refresh=true) override |

| Assess the status of the motor output with respect to load and supply. | |

| StatusSignal< signals::DifferentialControlModeValue > & | GetDifferentialControlMode (bool refresh=true) override |

| The active control mode of the differential controller. | |

| StatusSignal< units::angular_velocity::turns_per_second_t > & | GetDifferentialAverageVelocity (bool refresh=true) override |

| Average component of the differential velocity of device. | |

| StatusSignal< units::angle::turn_t > & | GetDifferentialAveragePosition (bool refresh=true) override |

| Average component of the differential position of device. | |

| StatusSignal< units::angular_velocity::turns_per_second_t > & | GetDifferentialDifferenceVelocity (bool refresh=true) override |

| Difference component of the differential velocity of device. | |

| StatusSignal< units::angle::turn_t > & | GetDifferentialDifferencePosition (bool refresh=true) override |

| Difference component of the differential position of device. | |

| StatusSignal< int > & | GetDifferentialClosedLoopSlot (bool refresh=true) override |

| The slot that the closed-loop differential PID is using. | |

| StatusSignal< ctre::unit::newton_meters_per_ampere_t > & | GetMotorKT (bool refresh=true) override |

| The torque constant (K_T) of the motor. | |

| StatusSignal< ctre::unit::rpm_per_volt_t > & | GetMotorKV (bool refresh=true) override |

| The velocity constant (K_V) of the motor. | |

| StatusSignal< units::current::ampere_t > & | GetMotorStallCurrent (bool refresh=true) override |

| The stall current of the motor at 12 V output. | |

| StatusSignal< signals::BridgeOutputValue > & | GetBridgeOutput (bool refresh=true) override |

| The applied output of the bridge. | |

| StatusSignal< bool > & | GetIsProLicensed (bool refresh=true) override |

| Whether the device is Phoenix Pro licensed. | |

| StatusSignal< units::temperature::celsius_t > & | GetAncillaryDeviceTemp (bool refresh=true) override |

| Temperature of device from second sensor. | |

| StatusSignal< signals::ConnectedMotorValue > & | GetConnectedMotor (bool refresh=true) override |

| The type of motor attached to the Talon. | |

| StatusSignal< bool > & | GetFault_Hardware (bool refresh=true) override |

| Hardware fault occurred. | |

| StatusSignal< bool > & | GetStickyFault_Hardware (bool refresh=true) override |

| Hardware fault occurred. | |

| StatusSignal< bool > & | GetFault_ProcTemp (bool refresh=true) override |

| Processor temperature exceeded limit. | |

| StatusSignal< bool > & | GetStickyFault_ProcTemp (bool refresh=true) override |

| Processor temperature exceeded limit. | |

| StatusSignal< bool > & | GetFault_DeviceTemp (bool refresh=true) override |

| Device temperature exceeded limit. | |

| StatusSignal< bool > & | GetStickyFault_DeviceTemp (bool refresh=true) override |

| Device temperature exceeded limit. | |

| StatusSignal< bool > & | GetFault_Undervoltage (bool refresh=true) override |

| Device supply voltage dropped to near brownout levels. | |

| StatusSignal< bool > & | GetStickyFault_Undervoltage (bool refresh=true) override |

| Device supply voltage dropped to near brownout levels. | |

| StatusSignal< bool > & | GetFault_BootDuringEnable (bool refresh=true) override |

| Device boot while detecting the enable signal. | |

| StatusSignal< bool > & | GetStickyFault_BootDuringEnable (bool refresh=true) override |

| Device boot while detecting the enable signal. | |

| StatusSignal< bool > & | GetFault_UnlicensedFeatureInUse (bool refresh=true) override |

| An unlicensed feature is in use, device may not behave as expected. | |

| StatusSignal< bool > & | GetStickyFault_UnlicensedFeatureInUse (bool refresh=true) override |

| An unlicensed feature is in use, device may not behave as expected. | |

| StatusSignal< bool > & | GetFault_BridgeBrownout (bool refresh=true) override |

| Bridge was disabled most likely due to supply voltage dropping too low. | |

| StatusSignal< bool > & | GetStickyFault_BridgeBrownout (bool refresh=true) override |

| Bridge was disabled most likely due to supply voltage dropping too low. | |

| StatusSignal< bool > & | GetFault_RemoteSensorReset (bool refresh=true) override |

| The remote sensor has reset. | |

| StatusSignal< bool > & | GetStickyFault_RemoteSensorReset (bool refresh=true) override |

| The remote sensor has reset. | |

| StatusSignal< bool > & | GetFault_MissingDifferentialFX (bool refresh=true) override |

| The remote Talon used for differential control is not present on CAN Bus. | |

| StatusSignal< bool > & | GetStickyFault_MissingDifferentialFX (bool refresh=true) override |

| The remote Talon used for differential control is not present on CAN Bus. | |

| StatusSignal< bool > & | GetFault_RemoteSensorPosOverflow (bool refresh=true) override |

| The remote sensor position has overflowed. | |

| StatusSignal< bool > & | GetStickyFault_RemoteSensorPosOverflow (bool refresh=true) override |

| The remote sensor position has overflowed. | |

| StatusSignal< bool > & | GetFault_OverSupplyV (bool refresh=true) override |

| Supply Voltage has exceeded the maximum voltage rating of device. | |

| StatusSignal< bool > & | GetStickyFault_OverSupplyV (bool refresh=true) override |

| Supply Voltage has exceeded the maximum voltage rating of device. | |

| StatusSignal< bool > & | GetFault_UnstableSupplyV (bool refresh=true) override |

| Supply Voltage is unstable. | |

| StatusSignal< bool > & | GetStickyFault_UnstableSupplyV (bool refresh=true) override |

| Supply Voltage is unstable. | |

| StatusSignal< bool > & | GetFault_ReverseHardLimit (bool refresh=true) override |

| Reverse limit switch has been asserted. | |

| StatusSignal< bool > & | GetStickyFault_ReverseHardLimit (bool refresh=true) override |

| Reverse limit switch has been asserted. | |

| StatusSignal< bool > & | GetFault_ForwardHardLimit (bool refresh=true) override |

| Forward limit switch has been asserted. | |

| StatusSignal< bool > & | GetStickyFault_ForwardHardLimit (bool refresh=true) override |

| Forward limit switch has been asserted. | |

| StatusSignal< bool > & | GetFault_ReverseSoftLimit (bool refresh=true) override |

| Reverse soft limit has been asserted. | |

| StatusSignal< bool > & | GetStickyFault_ReverseSoftLimit (bool refresh=true) override |

| Reverse soft limit has been asserted. | |

| StatusSignal< bool > & | GetFault_ForwardSoftLimit (bool refresh=true) override |

| Forward soft limit has been asserted. | |

| StatusSignal< bool > & | GetStickyFault_ForwardSoftLimit (bool refresh=true) override |

| Forward soft limit has been asserted. | |

| StatusSignal< bool > & | GetFault_MissingSoftLimitRemote (bool refresh=true) override |

| The remote soft limit device is not present on CAN Bus. | |

| StatusSignal< bool > & | GetStickyFault_MissingSoftLimitRemote (bool refresh=true) override |

| The remote soft limit device is not present on CAN Bus. | |

| StatusSignal< bool > & | GetFault_MissingHardLimitRemote (bool refresh=true) override |

| The remote limit switch device is not present on CAN Bus. | |

| StatusSignal< bool > & | GetStickyFault_MissingHardLimitRemote (bool refresh=true) override |

| The remote limit switch device is not present on CAN Bus. | |

| StatusSignal< bool > & | GetFault_RemoteSensorDataInvalid (bool refresh=true) override |

| The remote sensor's data is no longer trusted. | |

| StatusSignal< bool > & | GetStickyFault_RemoteSensorDataInvalid (bool refresh=true) override |

| The remote sensor's data is no longer trusted. | |

| StatusSignal< bool > & | GetFault_FusedSensorOutOfSync (bool refresh=true) override |

| The remote sensor used for fusion has fallen out of sync to the local sensor. | |

| StatusSignal< bool > & | GetStickyFault_FusedSensorOutOfSync (bool refresh=true) override |

| The remote sensor used for fusion has fallen out of sync to the local sensor. | |

| StatusSignal< bool > & | GetFault_StatorCurrLimit (bool refresh=true) override |

| Stator current limit occured. | |

| StatusSignal< bool > & | GetStickyFault_StatorCurrLimit (bool refresh=true) override |

| Stator current limit occured. | |

| StatusSignal< bool > & | GetFault_SupplyCurrLimit (bool refresh=true) override |

| Supply current limit occured. | |

| StatusSignal< bool > & | GetStickyFault_SupplyCurrLimit (bool refresh=true) override |

| Supply current limit occured. | |

| StatusSignal< bool > & | GetFault_UsingFusedCANcoderWhileUnlicensed (bool refresh=true) override |

| Using Fused CANcoder feature while unlicensed. | |

| StatusSignal< bool > & | GetStickyFault_UsingFusedCANcoderWhileUnlicensed (bool refresh=true) override |

| Using Fused CANcoder feature while unlicensed. | |

| StatusSignal< bool > & | GetFault_StaticBrakeDisabled (bool refresh=true) override |

| Static brake was momentarily disabled due to excessive braking current while disabled. | |

| StatusSignal< bool > & | GetStickyFault_StaticBrakeDisabled (bool refresh=true) override |

| Static brake was momentarily disabled due to excessive braking current while disabled. | |

| StatusSignal< double > & | GetClosedLoopProportionalOutput (bool refresh=true) override |

| Closed loop proportional component. | |

| StatusSignal< double > & | GetClosedLoopIntegratedOutput (bool refresh=true) override |

| Closed loop integrated component. | |

| StatusSignal< double > & | GetClosedLoopFeedForward (bool refresh=true) override |

| Feedforward passed by the user. | |

| StatusSignal< double > & | GetClosedLoopDerivativeOutput (bool refresh=true) override |

| Closed loop derivative component. | |

| StatusSignal< double > & | GetClosedLoopOutput (bool refresh=true) override |

| Closed loop total output. | |

| StatusSignal< double > & | GetClosedLoopReference (bool refresh=true) override |

| Value that the closed loop is targeting. | |

| StatusSignal< double > & | GetClosedLoopReferenceSlope (bool refresh=true) override |

| Derivative of the target that the closed loop is targeting. | |

| StatusSignal< double > & | GetClosedLoopError (bool refresh=true) override |

| The difference between target reference and current measurement. | |

| StatusSignal< double > & | GetDifferentialOutput (bool refresh=true) override |

| The calculated motor output for differential followers. | |

| StatusSignal< double > & | GetDifferentialClosedLoopProportionalOutput (bool refresh=true) override |

| Differential closed loop proportional component. | |

| StatusSignal< double > & | GetDifferentialClosedLoopIntegratedOutput (bool refresh=true) override |

| Differential closed loop integrated component. | |

| StatusSignal< double > & | GetDifferentialClosedLoopFeedForward (bool refresh=true) override |

| Differential Feedforward passed by the user. | |

| StatusSignal< double > & | GetDifferentialClosedLoopDerivativeOutput (bool refresh=true) override |

| Differential closed loop derivative component. | |

| StatusSignal< double > & | GetDifferentialClosedLoopOutput (bool refresh=true) override |

| Differential closed loop total output. | |

| StatusSignal< double > & | GetDifferentialClosedLoopReference (bool refresh=true) override |

| Value that the differential closed loop is targeting. | |

| StatusSignal< double > & | GetDifferentialClosedLoopReferenceSlope (bool refresh=true) override |

| Derivative of the target that the differential closed loop is targeting. | |

| StatusSignal< double > & | GetDifferentialClosedLoopError (bool refresh=true) override |

| The difference between target differential reference and current measurement. | |

| ctre::phoenix::StatusCode | SetControl (const controls::DutyCycleOut &request) override |

| Request a specified motor duty cycle. | |

| ctre::phoenix::StatusCode | SetControl (const controls::TorqueCurrentFOC &request) override |

| Request a specified motor current (field oriented control). | |

| ctre::phoenix::StatusCode | SetControl (const controls::VoltageOut &request) override |

| Request a specified voltage. | |

| ctre::phoenix::StatusCode | SetControl (const controls::PositionDutyCycle &request) override |

| Request PID to target position with duty cycle feedforward. | |

| ctre::phoenix::StatusCode | SetControl (const controls::PositionVoltage &request) override |

| Request PID to target position with voltage feedforward. | |

| ctre::phoenix::StatusCode | SetControl (const controls::PositionTorqueCurrentFOC &request) override |

| Request PID to target position with torque current feedforward. | |

| ctre::phoenix::StatusCode | SetControl (const controls::VelocityDutyCycle &request) override |

| Request PID to target velocity with duty cycle feedforward. | |

| ctre::phoenix::StatusCode | SetControl (const controls::VelocityVoltage &request) override |

| Request PID to target velocity with voltage feedforward. | |

| ctre::phoenix::StatusCode | SetControl (const controls::VelocityTorqueCurrentFOC &request) override |

| Request PID to target velocity with torque current feedforward. | |

| ctre::phoenix::StatusCode | SetControl (const controls::MotionMagicDutyCycle &request) override |

| Requests Motion Magic® to target a final position using a motion profile. | |

| ctre::phoenix::StatusCode | SetControl (const controls::MotionMagicVoltage &request) override |

| Requests Motion Magic® to target a final position using a motion profile. | |

| ctre::phoenix::StatusCode | SetControl (const controls::MotionMagicTorqueCurrentFOC &request) override |

| Requests Motion Magic® to target a final position using a motion profile. | |

| ctre::phoenix::StatusCode | SetControl (const controls::DifferentialDutyCycle &request) override |

| Request a specified motor duty cycle with a differential position closed-loop. | |

| ctre::phoenix::StatusCode | SetControl (const controls::DifferentialVoltage &request) override |

| Request a specified voltage with a differential position closed-loop. | |

| ctre::phoenix::StatusCode | SetControl (const controls::DifferentialPositionDutyCycle &request) override |

| Request PID to target position with a differential position setpoint. | |

| ctre::phoenix::StatusCode | SetControl (const controls::DifferentialPositionVoltage &request) override |

| Request PID to target position with a differential position setpoint. | |

| ctre::phoenix::StatusCode | SetControl (const controls::DifferentialVelocityDutyCycle &request) override |

| Request PID to target velocity with a differential position setpoint. | |

| ctre::phoenix::StatusCode | SetControl (const controls::DifferentialVelocityVoltage &request) override |

| Request PID to target velocity with a differential position setpoint. | |

| ctre::phoenix::StatusCode | SetControl (const controls::DifferentialMotionMagicDutyCycle &request) override |

| Requests Motion Magic® to target a final position using a motion profile, and PID to a differential position setpoint. | |

| ctre::phoenix::StatusCode | SetControl (const controls::DifferentialMotionMagicVoltage &request) override |

| Requests Motion Magic® to target a final position using a motion profile, and PID to a differential position setpoint. | |

| ctre::phoenix::StatusCode | SetControl (const controls::Follower &request) override |

| Follow the motor output of another Talon. | |

| ctre::phoenix::StatusCode | SetControl (const controls::StrictFollower &request) override |

| Follow the motor output of another Talon while ignoring the master's invert setting. | |

| ctre::phoenix::StatusCode | SetControl (const controls::DifferentialFollower &request) override |

| Follow the differential motor output of another Talon. | |

| ctre::phoenix::StatusCode | SetControl (const controls::DifferentialStrictFollower &request) override |

| Follow the differential motor output of another Talon while ignoring the master's invert setting. | |

| ctre::phoenix::StatusCode | SetControl (const controls::NeutralOut &request) override |

| Request neutral output of actuator. | |

| ctre::phoenix::StatusCode | SetControl (const controls::CoastOut &request) override |

| Request coast neutral output of actuator. | |

| ctre::phoenix::StatusCode | SetControl (const controls::StaticBrake &request) override |

| Applies full neutral-brake by shorting motor leads together. | |

| ctre::phoenix::StatusCode | SetControl (const controls::MusicTone &request) override |

| Plays a single tone at the user specified frequency. | |

| ctre::phoenix::StatusCode | SetControl (const controls::MotionMagicVelocityDutyCycle &request) override |

| Requests Motion Magic® to target a final velocity using a motion profile. | |

| ctre::phoenix::StatusCode | SetControl (const controls::MotionMagicVelocityTorqueCurrentFOC &request) override |

| Requests Motion Magic® to target a final velocity using a motion profile. | |

| ctre::phoenix::StatusCode | SetControl (const controls::MotionMagicVelocityVoltage &request) override |

| Requests Motion Magic® to target a final velocity using a motion profile. | |

| ctre::phoenix::StatusCode | SetControl (const controls::MotionMagicExpoDutyCycle &request) override |

| Requests Motion Magic® to target a final position using an exponential motion profile. | |

| ctre::phoenix::StatusCode | SetControl (const controls::MotionMagicExpoVoltage &request) override |

| Requests Motion Magic® to target a final position using an exponential motion profile. | |

| ctre::phoenix::StatusCode | SetControl (const controls::MotionMagicExpoTorqueCurrentFOC &request) override |

| Requests Motion Magic® to target a final position using an exponential motion profile. | |

| ctre::phoenix::StatusCode | SetControl (const controls::DynamicMotionMagicDutyCycle &request) override |

| Requests Motion Magic® to target a final position using a motion profile. | |

| ctre::phoenix::StatusCode | SetControl (const controls::DynamicMotionMagicVoltage &request) override |

| Requests Motion Magic® to target a final position using a motion profile. | |

| ctre::phoenix::StatusCode | SetControl (const controls::DynamicMotionMagicTorqueCurrentFOC &request) override |

| Requests Motion Magic® to target a final position using a motion profile. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_DutyCycleOut_Position &request) override |

| Differential control with duty cycle average target and position difference target. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_PositionDutyCycle_Position &request) override |

| Differential control with position average target and position difference target using dutycycle control. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_VelocityDutyCycle_Position &request) override |

| Differential control with velocity average target and position difference target using dutycycle control. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_MotionMagicDutyCycle_Position &request) override |

| Differential control with Motion Magic® average target and position difference target using dutycycle control. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_DutyCycleOut_Velocity &request) override |

| Differential control with duty cycle average target and velocity difference target. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_PositionDutyCycle_Velocity &request) override |

| Differential control with position average target and velocity difference target using dutycycle control. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_VelocityDutyCycle_Velocity &request) override |

| Differential control with velocity average target and velocity difference target using dutycycle control. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_MotionMagicDutyCycle_Velocity &request) override |

| Differential control with Motion Magic® average target and velocity difference target using dutycycle control. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_VoltageOut_Position &request) override |

| Differential control with voltage average target and position difference target. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_PositionVoltage_Position &request) override |

| Differential control with position average target and position difference target using voltage control. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_VelocityVoltage_Position &request) override |

| Differential control with velocity average target and position difference target using voltage control. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_MotionMagicVoltage_Position &request) override |

| Differential control with Motion Magic® average target and position difference target using voltage control. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_VoltageOut_Velocity &request) override |

| Differential control with voltage average target and velocity difference target. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_PositionVoltage_Velocity &request) override |

| Differential control with position average target and velocity difference target using voltage control. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_VelocityVoltage_Velocity &request) override |

| Differential control with velocity average target and velocity difference target using voltage control. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_MotionMagicVoltage_Velocity &request) override |

| Differential control with Motion Magic® average target and velocity difference target using voltage control. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_TorqueCurrentFOC_Position &request) override |

| Differential control with torque current average target and position difference target. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_PositionTorqueCurrentFOC_Position &request) override |

| Differential control with position average target and position difference target using torque current control. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_VelocityTorqueCurrentFOC_Position &request) override |

| Differential control with velocity average target and position difference target using torque current control. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_MotionMagicTorqueCurrentFOC_Position &request) override |

| Differential control with Motion Magic® average target and position difference target using torque current control. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_TorqueCurrentFOC_Velocity &request) override |

| Differential control with torque current average target and velocity difference target. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_PositionTorqueCurrentFOC_Velocity &request) override |

| Differential control with position average target and velocity difference target using torque current control. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_VelocityTorqueCurrentFOC_Velocity &request) override |

| Differential control with velocity average target and velocity difference target using torque current control. | |

| ctre::phoenix::StatusCode | SetControl (const controls::compound::Diff_MotionMagicTorqueCurrentFOC_Velocity &request) override |

| Differential control with Motion Magic® average target and velocity difference target using torque current control. | |

| ctre::phoenix::StatusCode | SetControl (const controls::ControlRequest &request) override |

| Control device with generic control request object. | |

| ctre::phoenix::StatusCode | SetPosition (units::angle::turn_t newValue, units::time::second_t timeoutSeconds) override |

| Sets the mechanism position of the device in mechanism rotations. | |

| ctre::phoenix::StatusCode | SetPosition (units::angle::turn_t newValue) override |

| Sets the mechanism position of the device in mechanism rotations. | |

| ctre::phoenix::StatusCode | ClearStickyFaults (units::time::second_t timeoutSeconds) override |

| Clear the sticky faults in the device. | |

| ctre::phoenix::StatusCode | ClearStickyFaults () override |

| Clear the sticky faults in the device. | |

| ctre::phoenix::StatusCode | ClearStickyFault_Hardware (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: Hardware fault occurred. | |

| ctre::phoenix::StatusCode | ClearStickyFault_Hardware () override |

| Clear sticky fault: Hardware fault occurred. | |

| ctre::phoenix::StatusCode | ClearStickyFault_ProcTemp (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: Processor temperature exceeded limit. | |

| ctre::phoenix::StatusCode | ClearStickyFault_ProcTemp () override |

| Clear sticky fault: Processor temperature exceeded limit. | |

| ctre::phoenix::StatusCode | ClearStickyFault_DeviceTemp (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: Device temperature exceeded limit. | |

| ctre::phoenix::StatusCode | ClearStickyFault_DeviceTemp () override |

| Clear sticky fault: Device temperature exceeded limit. | |

| ctre::phoenix::StatusCode | ClearStickyFault_Undervoltage (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: Device supply voltage dropped to near brownout levels. | |

| ctre::phoenix::StatusCode | ClearStickyFault_Undervoltage () override |

| Clear sticky fault: Device supply voltage dropped to near brownout levels. | |

| ctre::phoenix::StatusCode | ClearStickyFault_BootDuringEnable (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: Device boot while detecting the enable signal. | |

| ctre::phoenix::StatusCode | ClearStickyFault_BootDuringEnable () override |

| Clear sticky fault: Device boot while detecting the enable signal. | |

| ctre::phoenix::StatusCode | ClearStickyFault_UnlicensedFeatureInUse (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: An unlicensed feature is in use, device may not behave as expected. | |

| ctre::phoenix::StatusCode | ClearStickyFault_UnlicensedFeatureInUse () override |

| Clear sticky fault: An unlicensed feature is in use, device may not behave as expected. | |

| ctre::phoenix::StatusCode | ClearStickyFault_BridgeBrownout (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: Bridge was disabled most likely due to supply voltage dropping too low. | |

| ctre::phoenix::StatusCode | ClearStickyFault_BridgeBrownout () override |

| Clear sticky fault: Bridge was disabled most likely due to supply voltage dropping too low. | |

| ctre::phoenix::StatusCode | ClearStickyFault_RemoteSensorReset (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: The remote sensor has reset. | |

| ctre::phoenix::StatusCode | ClearStickyFault_RemoteSensorReset () override |

| Clear sticky fault: The remote sensor has reset. | |

| ctre::phoenix::StatusCode | ClearStickyFault_MissingDifferentialFX (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: The remote Talon used for differential control is not present on CAN Bus. | |

| ctre::phoenix::StatusCode | ClearStickyFault_MissingDifferentialFX () override |

| Clear sticky fault: The remote Talon used for differential control is not present on CAN Bus. | |

| ctre::phoenix::StatusCode | ClearStickyFault_RemoteSensorPosOverflow (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: The remote sensor position has overflowed. | |

| ctre::phoenix::StatusCode | ClearStickyFault_RemoteSensorPosOverflow () override |

| Clear sticky fault: The remote sensor position has overflowed. | |

| ctre::phoenix::StatusCode | ClearStickyFault_OverSupplyV (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: Supply Voltage has exceeded the maximum voltage rating of device. | |

| ctre::phoenix::StatusCode | ClearStickyFault_OverSupplyV () override |

| Clear sticky fault: Supply Voltage has exceeded the maximum voltage rating of device. | |

| ctre::phoenix::StatusCode | ClearStickyFault_UnstableSupplyV (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: Supply Voltage is unstable. | |

| ctre::phoenix::StatusCode | ClearStickyFault_UnstableSupplyV () override |

| Clear sticky fault: Supply Voltage is unstable. | |

| ctre::phoenix::StatusCode | ClearStickyFault_ReverseHardLimit (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: Reverse limit switch has been asserted. | |

| ctre::phoenix::StatusCode | ClearStickyFault_ReverseHardLimit () override |

| Clear sticky fault: Reverse limit switch has been asserted. | |

| ctre::phoenix::StatusCode | ClearStickyFault_ForwardHardLimit (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: Forward limit switch has been asserted. | |

| ctre::phoenix::StatusCode | ClearStickyFault_ForwardHardLimit () override |

| Clear sticky fault: Forward limit switch has been asserted. | |

| ctre::phoenix::StatusCode | ClearStickyFault_ReverseSoftLimit (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: Reverse soft limit has been asserted. | |

| ctre::phoenix::StatusCode | ClearStickyFault_ReverseSoftLimit () override |

| Clear sticky fault: Reverse soft limit has been asserted. | |

| ctre::phoenix::StatusCode | ClearStickyFault_ForwardSoftLimit (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: Forward soft limit has been asserted. | |

| ctre::phoenix::StatusCode | ClearStickyFault_ForwardSoftLimit () override |

| Clear sticky fault: Forward soft limit has been asserted. | |

| ctre::phoenix::StatusCode | ClearStickyFault_MissingSoftLimitRemote (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: The remote soft limit device is not present on CAN Bus. | |

| ctre::phoenix::StatusCode | ClearStickyFault_MissingSoftLimitRemote () override |

| Clear sticky fault: The remote soft limit device is not present on CAN Bus. | |

| ctre::phoenix::StatusCode | ClearStickyFault_MissingHardLimitRemote (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: The remote limit switch device is not present on CAN Bus. | |

| ctre::phoenix::StatusCode | ClearStickyFault_MissingHardLimitRemote () override |

| Clear sticky fault: The remote limit switch device is not present on CAN Bus. | |

| ctre::phoenix::StatusCode | ClearStickyFault_RemoteSensorDataInvalid (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: The remote sensor's data is no longer trusted. | |

| ctre::phoenix::StatusCode | ClearStickyFault_RemoteSensorDataInvalid () override |

| Clear sticky fault: The remote sensor's data is no longer trusted. | |

| ctre::phoenix::StatusCode | ClearStickyFault_FusedSensorOutOfSync (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: The remote sensor used for fusion has fallen out of sync to the local sensor. | |

| ctre::phoenix::StatusCode | ClearStickyFault_FusedSensorOutOfSync () override |

| Clear sticky fault: The remote sensor used for fusion has fallen out of sync to the local sensor. | |

| ctre::phoenix::StatusCode | ClearStickyFault_StatorCurrLimit (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: Stator current limit occured. | |

| ctre::phoenix::StatusCode | ClearStickyFault_StatorCurrLimit () override |

| Clear sticky fault: Stator current limit occured. | |

| ctre::phoenix::StatusCode | ClearStickyFault_SupplyCurrLimit (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: Supply current limit occured. | |

| ctre::phoenix::StatusCode | ClearStickyFault_SupplyCurrLimit () override |

| Clear sticky fault: Supply current limit occured. | |

| ctre::phoenix::StatusCode | ClearStickyFault_UsingFusedCANcoderWhileUnlicensed (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: Using Fused CANcoder feature while unlicensed. | |

| ctre::phoenix::StatusCode | ClearStickyFault_UsingFusedCANcoderWhileUnlicensed () override |

| Clear sticky fault: Using Fused CANcoder feature while unlicensed. | |

| ctre::phoenix::StatusCode | ClearStickyFault_StaticBrakeDisabled (units::time::second_t timeoutSeconds) override |

| Clear sticky fault: Static brake was momentarily disabled due to excessive braking current while disabled. | |

| ctre::phoenix::StatusCode | ClearStickyFault_StaticBrakeDisabled () override |

| Clear sticky fault: Static brake was momentarily disabled due to excessive braking current while disabled. | |

Public Member Functions inherited from ctre::phoenix6::hardware::ParentDevice Public Member Functions inherited from ctre::phoenix6::hardware::ParentDevice | |

| ParentDevice (int deviceID, std::string model, std::string canbus) | |

| virtual | ~ParentDevice ()=default |

| ParentDevice (ParentDevice const &)=delete | |

| ParentDevice & | operator= (ParentDevice const &)=delete |

| int | GetDeviceID () const |

| const std::string & | GetNetwork () const |

| uint64_t | GetDeviceHash () const |

| Gets a number unique for this device's hardware type and ID. | |

| std::shared_ptr< const controls::ControlRequest > | GetAppliedControl () const |

| Get the latest applied control. | |

| std::shared_ptr< controls::ControlRequest > | GetAppliedControl () |

| Get the latest applied control. | |

| bool | HasResetOccurred () |

| std::function< bool()> | GetResetOccurredChecker () const |

| bool | IsConnected (units::second_t maxLatencySeconds=500_ms) |

| Returns whether the device is still connected to the robot. | |

| StatusSignal< double > & | GetGenericSignal (uint32_t signal, bool refresh=true) |

| This is a reserved routine for internal testing. | |

| ctre::phoenix::StatusCode | OptimizeBusUtilization (units::frequency::hertz_t optimizedFreqHz=0_Hz, units::time::second_t timeoutSeconds=100_ms) |

| Optimizes the device's bus utilization by reducing the update frequencies of its status signals. | |

| ctre::phoenix::StatusCode | ResetSignalFrequencies (units::time::second_t timeoutSeconds=100_ms) |

| Resets the update frequencies of all the device's status signals to the defaults. | |

Public Member Functions inherited from ctre::phoenix6::hardware::traits::CommonTalonWithFOC Public Member Functions inherited from ctre::phoenix6::hardware::traits::CommonTalonWithFOC | |

| virtual | ~CommonTalonWithFOC ()=default |

Public Member Functions inherited from ctre::phoenix6::hardware::traits::CommonTalon Public Member Functions inherited from ctre::phoenix6::hardware::traits::CommonTalon | |

| virtual | ~CommonTalon ()=default |

Public Member Functions inherited from ctre::phoenix6::hardware::traits::HasTalonControls Public Member Functions inherited from ctre::phoenix6::hardware::traits::HasTalonControls | |

| virtual | ~HasTalonControls ()=default |

Public Member Functions inherited from ctre::phoenix6::hardware::traits::HasTalonSignals Public Member Functions inherited from ctre::phoenix6::hardware::traits::HasTalonSignals | |

| virtual | ~HasTalonSignals ()=default |

Public Member Functions inherited from ctre::phoenix6::hardware::traits::SupportsFOC Public Member Functions inherited from ctre::phoenix6::hardware::traits::SupportsFOC | |

| virtual | ~SupportsFOC ()=default |

Public Member Functions inherited from ctre::phoenix6::hardware::traits::SupportsMusic Public Member Functions inherited from ctre::phoenix6::hardware::traits::SupportsMusic | |

| virtual | ~SupportsMusic ()=default |

Additional Inherited Members | |

Static Public Member Functions inherited from ctre::phoenix6::hardware::ParentDevice Static Public Member Functions inherited from ctre::phoenix6::hardware::ParentDevice | |

| template<typename... Devices, typename = std::enable_if_t<is_all_device_v<Devices...>>> | |

| static ctre::phoenix::StatusCode | OptimizeBusUtilizationForAll (Devices &... devices) |

| Optimizes the bus utilization of the provided devices by reducing the update frequencies of their status signals. | |

| static ctre::phoenix::StatusCode | OptimizeBusUtilizationForAll (const std::vector< ParentDevice * > &devices) |

| Optimizes the bus utilization of the provided devices by reducing the update frequencies of their status signals. | |

| template<size_t N> | |

| static ctre::phoenix::StatusCode | OptimizeBusUtilizationForAll (const std::array< ParentDevice *, N > &devices) |

| Optimizes the bus utilization of the provided devices by reducing the update frequencies of their status signals. | |

| template<typename... Devices, typename = std::enable_if_t<is_all_device_v<Devices...>>> | |

| static ctre::phoenix::StatusCode | OptimizeBusUtilizationForAll (units::frequency::hertz_t optimizedFreqHz, Devices &... devices) |

| Optimizes the bus utilization of the provided devices by reducing the update frequencies of their status signals. | |

| static ctre::phoenix::StatusCode | OptimizeBusUtilizationForAll (units::frequency::hertz_t optimizedFreqHz, const std::vector< ParentDevice * > &devices) |

| Optimizes the bus utilization of the provided devices by reducing the update frequencies of their status signals. | |

| template<size_t N> | |

| static ctre::phoenix::StatusCode | OptimizeBusUtilizationForAll (units::frequency::hertz_t optimizedFreqHz, const std::array< ParentDevice *, N > &devices) |

| Optimizes the bus utilization of the provided devices by reducing the update frequencies of their status signals. | |

| template<typename... Devices, typename = std::enable_if_t<is_all_device_v<Devices...>>> | |

| static ctre::phoenix::StatusCode | ResetSignalFrequenciesForAll (Devices &... devices) |

| Resets the update frequencies of all the devices' status signals to the defaults. | |

| static ctre::phoenix::StatusCode | ResetSignalFrequenciesForAll (const std::vector< ParentDevice * > &devices) |

| Resets the update frequencies of all the devices' status signals to the defaults. | |

| template<size_t N> | |

| static ctre::phoenix::StatusCode | ResetSignalFrequenciesForAll (const std::array< ParentDevice *, N > &devices) |

| Resets the update frequencies of all the devices' status signals to the defaults. | |

Protected Member Functions inherited from ctre::phoenix6::hardware::ParentDevice Protected Member Functions inherited from ctre::phoenix6::hardware::ParentDevice | |

| virtual ctre::phoenix::StatusCode | SetControlPrivate (const controls::ControlRequest &request) |

| template<typename T > | |

| StatusSignal< T > & | LookupStatusSignal (uint16_t spn, std::string signalName, bool reportOnConstruction, bool refresh) |

| template<typename T > | |

| StatusSignal< T > & | LookupStatusSignal (uint16_t spn, std::function< std::map< uint16_t, std::string >()> mapFiller, std::string signalName, bool reportOnConstruction, bool refresh) |

| template<typename T , typename U > | |

| StatusSignal< T > | LookupDimensionlessStatusSignal (uint16_t spn, std::string signalName, bool refresh) |

| Returns a unitless version of the StatusSignal by value. | |

Protected Attributes inherited from ctre::phoenix6::hardware::ParentDevice Protected Attributes inherited from ctre::phoenix6::hardware::ParentDevice | |

| DeviceIdentifier | deviceIdentifier |

Static Protected Attributes inherited from ctre::phoenix6::hardware::ParentDevice Static Protected Attributes inherited from ctre::phoenix6::hardware::ParentDevice | |

| static controls::EmptyControl | _emptyControl {} |

| template<typename... Devices> | |

| static constexpr bool | is_all_device_v = is_all_device<Devices...>::value |

| Whether all types passed in are subclasses of ParentDevice. | |

Detailed Description

Class description for the Talon FX integrated motor controller.

Member Typedef Documentation

◆ Configuration

Constructor & Destructor Documentation

◆ CoreTalonFX() [1/2]

| ctre::phoenix6::hardware::core::CoreTalonFX::CoreTalonFX | ( | int | deviceId, |

| std::string | canbus = "" ) |

Constructs a new Talon FX motor controller object.

- Parameters

-

deviceId ID of the device, as configured in Phoenix Tuner. canbus Name of the CAN bus this device is on. Possible CAN bus strings are: - "rio" for the native roboRIO CAN bus

- CANivore name or serial number

- SocketCAN interface (non-FRC Linux only)

- "*" for any CANivore seen by the program

- empty string (default) to select the default for the system:

- "rio" on roboRIO

- "can0" on Linux

- "*" on Windows

◆ CoreTalonFX() [2/2]

|

inline |

Constructs a new Talon FX motor controller object.

- Parameters

-

deviceId ID of the device, as configured in Phoenix Tuner. canbus The CAN bus this device is on.

Member Function Documentation

◆ ClearStickyFault_BootDuringEnable() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: Device boot while detecting the enable signal.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_BootDuringEnable() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: Device boot while detecting the enable signal.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_BridgeBrownout() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: Bridge was disabled most likely due to supply voltage dropping too low.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_BridgeBrownout() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: Bridge was disabled most likely due to supply voltage dropping too low.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_DeviceTemp() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: Device temperature exceeded limit.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_DeviceTemp() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: Device temperature exceeded limit.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_ForwardHardLimit() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: Forward limit switch has been asserted.

Output is set to neutral.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_ForwardHardLimit() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: Forward limit switch has been asserted.

Output is set to neutral.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_ForwardSoftLimit() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: Forward soft limit has been asserted.

Output is set to neutral.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_ForwardSoftLimit() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: Forward soft limit has been asserted.

Output is set to neutral.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_FusedSensorOutOfSync() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: The remote sensor used for fusion has fallen out of sync to the local sensor.

A re-synchronization has occurred, which may cause a discontinuity. This typically happens if there is significant slop in the mechanism, or if the RotorToSensorRatio configuration parameter is incorrect.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_FusedSensorOutOfSync() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: The remote sensor used for fusion has fallen out of sync to the local sensor.

A re-synchronization has occurred, which may cause a discontinuity. This typically happens if there is significant slop in the mechanism, or if the RotorToSensorRatio configuration parameter is incorrect.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_Hardware() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: Hardware fault occurred.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_Hardware() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: Hardware fault occurred.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_MissingDifferentialFX() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: The remote Talon used for differential control is not present on CAN Bus.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_MissingDifferentialFX() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: The remote Talon used for differential control is not present on CAN Bus.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_MissingHardLimitRemote() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: The remote limit switch device is not present on CAN Bus.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_MissingHardLimitRemote() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: The remote limit switch device is not present on CAN Bus.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_MissingSoftLimitRemote() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: The remote soft limit device is not present on CAN Bus.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_MissingSoftLimitRemote() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: The remote soft limit device is not present on CAN Bus.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_OverSupplyV() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: Supply Voltage has exceeded the maximum voltage rating of device.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_OverSupplyV() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: Supply Voltage has exceeded the maximum voltage rating of device.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_ProcTemp() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: Processor temperature exceeded limit.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_ProcTemp() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: Processor temperature exceeded limit.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_RemoteSensorDataInvalid() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: The remote sensor's data is no longer trusted.

This can happen if the remote sensor disappears from the CAN bus or if the remote sensor indicates its data is no longer valid, such as when a CANcoder's magnet strength falls into the "red" range.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_RemoteSensorDataInvalid() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: The remote sensor's data is no longer trusted.

This can happen if the remote sensor disappears from the CAN bus or if the remote sensor indicates its data is no longer valid, such as when a CANcoder's magnet strength falls into the "red" range.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_RemoteSensorPosOverflow() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: The remote sensor position has overflowed.

Because of the nature of remote sensors, it is possible for the remote sensor position to overflow beyond what is supported by the status signal frame. However, this is rare and cannot occur over the course of an FRC match under normal use.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_RemoteSensorPosOverflow() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: The remote sensor position has overflowed.

Because of the nature of remote sensors, it is possible for the remote sensor position to overflow beyond what is supported by the status signal frame. However, this is rare and cannot occur over the course of an FRC match under normal use.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_RemoteSensorReset() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: The remote sensor has reset.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_RemoteSensorReset() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: The remote sensor has reset.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_ReverseHardLimit() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: Reverse limit switch has been asserted.

Output is set to neutral.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_ReverseHardLimit() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: Reverse limit switch has been asserted.

Output is set to neutral.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_ReverseSoftLimit() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: Reverse soft limit has been asserted.

Output is set to neutral.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_ReverseSoftLimit() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: Reverse soft limit has been asserted.

Output is set to neutral.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_StaticBrakeDisabled() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: Static brake was momentarily disabled due to excessive braking current while disabled.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_StaticBrakeDisabled() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: Static brake was momentarily disabled due to excessive braking current while disabled.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_StatorCurrLimit() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: Stator current limit occured.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_StatorCurrLimit() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: Stator current limit occured.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_SupplyCurrLimit() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: Supply current limit occured.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_SupplyCurrLimit() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: Supply current limit occured.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_Undervoltage() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: Device supply voltage dropped to near brownout levels.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_Undervoltage() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: Device supply voltage dropped to near brownout levels.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_UnlicensedFeatureInUse() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: An unlicensed feature is in use, device may not behave as expected.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_UnlicensedFeatureInUse() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: An unlicensed feature is in use, device may not behave as expected.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_UnstableSupplyV() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: Supply Voltage is unstable.

Ensure you are using a battery and current limited power supply.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_UnstableSupplyV() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: Supply Voltage is unstable.

Ensure you are using a battery and current limited power supply.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_UsingFusedCANcoderWhileUnlicensed() [1/2]

|

inlineoverridevirtual |

Clear sticky fault: Using Fused CANcoder feature while unlicensed.

Device has fallen back to remote CANcoder.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFault_UsingFusedCANcoderWhileUnlicensed() [2/2]

|

inlineoverridevirtual |

Clear sticky fault: Using Fused CANcoder feature while unlicensed.

Device has fallen back to remote CANcoder.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFaults() [1/2]

|

inlineoverridevirtual |

Clear the sticky faults in the device.

This typically has no impact on the device functionality. Instead, it just clears telemetry faults that are accessible via API and Tuner Self-Test.

This will wait up to 0.100 seconds (100ms) by default.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ ClearStickyFaults() [2/2]

|

inlineoverridevirtual |

Clear the sticky faults in the device.

This typically has no impact on the device functionality. Instead, it just clears telemetry faults that are accessible via API and Tuner Self-Test.

- Parameters

-

timeoutSeconds Maximum time to wait up to in seconds.

- Returns

- StatusCode of the set command

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ GetAcceleration()

|

overridevirtual |

Acceleration of the device in mechanism rotations per second².

This can be the acceleration of a remote sensor and is affected by the RotorToSensorRatio and SensorToMechanismRatio configs.

- Minimum Value: -2048.0

- Maximum Value: 2047.75

- Default Value: 0

- Units: rotations per second²

Default Rates:

- CAN 2.0: 50.0 Hz

- CAN FD: 100.0 Hz (TimeSynced with Pro)

This refreshes and returns a cached StatusSignal object.

- Parameters

-

refresh Whether to refresh the StatusSignal before returning it; defaults to true

- Returns

- Acceleration Status Signal Object

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ GetAncillaryDeviceTemp()

|

overridevirtual |

Temperature of device from second sensor.

Newer versions of Talon have multiple temperature measurement methods.

- Minimum Value: 0.0

- Maximum Value: 255.0

- Default Value: 0

- Units: ℃

Default Rates:

- CAN 2.0: 4.0 Hz

- CAN FD: 100.0 Hz (TimeSynced with Pro)

This refreshes and returns a cached StatusSignal object.

- Parameters

-

refresh Whether to refresh the StatusSignal before returning it; defaults to true

- Returns

- AncillaryDeviceTemp Status Signal Object

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ GetAppliedRotorPolarity()

|

overridevirtual |

The applied rotor polarity as seen from the front of the motor.

This typically is determined by the Inverted config, but can be overridden if using Follower features.

Default Rates:

- CAN 2.0: 100.0 Hz

- CAN FD: 100.0 Hz (TimeSynced with Pro)

This refreshes and returns a cached StatusSignal object.

- Parameters

-

refresh Whether to refresh the StatusSignal before returning it; defaults to true

- Returns

- AppliedRotorPolarity Status Signal Object

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ GetBridgeOutput()

|

overridevirtual |

The applied output of the bridge.

Default Rates:

- CAN 2.0: 100.0 Hz

- CAN FD: 100.0 Hz (TimeSynced with Pro)

This refreshes and returns a cached StatusSignal object.

- Parameters

-

refresh Whether to refresh the StatusSignal before returning it; defaults to true

- Returns

- BridgeOutput Status Signal Object

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ GetClosedLoopDerivativeOutput()

|

overridevirtual |

Closed loop derivative component.

The portion of the closed loop output that is the proportional to the deriviative the error. Alternatively, the d-Contribution of the closed loop output.

Default Rates:

- CAN 2.0: 4.0 Hz

- CAN FD: 100.0 Hz (TimeSynced with Pro)

This refreshes and returns a cached StatusSignal object.

- Parameters

-

refresh Whether to refresh the StatusSignal before returning it; defaults to true

- Returns

- ClosedLoopDerivativeOutput Status Signal object

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ GetClosedLoopError()

|

overridevirtual |

The difference between target reference and current measurement.

This is the value that is treated as the error in the PID loop.

Default Rates:

- CAN 2.0: 4.0 Hz

- CAN FD: 100.0 Hz (TimeSynced with Pro)

This refreshes and returns a cached StatusSignal object.

- Parameters

-

refresh Whether to refresh the StatusSignal before returning it; defaults to true

- Returns

- ClosedLoopError Status Signal object

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ GetClosedLoopFeedForward()

|

overridevirtual |

Feedforward passed by the user.

This is the general feedforward that the user provides for the closed loop.

Default Rates:

- CAN 2.0: 4.0 Hz

- CAN FD: 100.0 Hz (TimeSynced with Pro)

This refreshes and returns a cached StatusSignal object.

- Parameters

-

refresh Whether to refresh the StatusSignal before returning it; defaults to true

- Returns

- ClosedLoopFeedForward Status Signal object

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ GetClosedLoopIntegratedOutput()

|

overridevirtual |

Closed loop integrated component.

The portion of the closed loop output that is proportional to the integrated error. Alternatively, the i-Contribution of the closed loop output.

Default Rates:

- CAN 2.0: 4.0 Hz

- CAN FD: 100.0 Hz (TimeSynced with Pro)

This refreshes and returns a cached StatusSignal object.

- Parameters

-

refresh Whether to refresh the StatusSignal before returning it; defaults to true

- Returns

- ClosedLoopIntegratedOutput Status Signal object

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ GetClosedLoopOutput()

|

overridevirtual |

Closed loop total output.

The total output of the closed loop output.

Default Rates:

- CAN 2.0: 4.0 Hz

- CAN FD: 100.0 Hz (TimeSynced with Pro)

This refreshes and returns a cached StatusSignal object.

- Parameters

-

refresh Whether to refresh the StatusSignal before returning it; defaults to true

- Returns

- ClosedLoopOutput Status Signal object

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ GetClosedLoopProportionalOutput()

|

overridevirtual |

Closed loop proportional component.

The portion of the closed loop output that is the proportional to the error. Alternatively, the p-Contribution of the closed loop output.

Default Rates:

- CAN 2.0: 4.0 Hz

- CAN FD: 100.0 Hz (TimeSynced with Pro)

This refreshes and returns a cached StatusSignal object.

- Parameters

-

refresh Whether to refresh the StatusSignal before returning it; defaults to true

- Returns

- ClosedLoopProportionalOutput Status Signal object

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ GetClosedLoopReference()

|

overridevirtual |

Value that the closed loop is targeting.

This is the value that the closed loop PID controller targets.

Default Rates:

- CAN 2.0: 4.0 Hz

- CAN FD: 100.0 Hz (TimeSynced with Pro)

This refreshes and returns a cached StatusSignal object.

- Parameters

-

refresh Whether to refresh the StatusSignal before returning it; defaults to true

- Returns

- ClosedLoopReference Status Signal object

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ GetClosedLoopReferenceSlope()

|

overridevirtual |

Derivative of the target that the closed loop is targeting.

This is the change in the closed loop reference. This may be used in the feed-forward calculation, the derivative-error, or in application of the signage for kS. Typically, this represents the target velocity during Motion Magic®.

Default Rates:

- CAN 2.0: 4.0 Hz

- CAN FD: 100.0 Hz (TimeSynced with Pro)

This refreshes and returns a cached StatusSignal object.

- Parameters

-

refresh Whether to refresh the StatusSignal before returning it; defaults to true

- Returns

- ClosedLoopReferenceSlope Status Signal object

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ GetClosedLoopSlot()

|

overridevirtual |

The slot that the closed-loop PID is using.

- Minimum Value: 0

- Maximum Value: 2

- Default Value: 0

- Units:

Default Rates:

- CAN 2.0: 4.0 Hz

- CAN FD: 100.0 Hz (TimeSynced with Pro)

This refreshes and returns a cached StatusSignal object.

- Parameters

-

refresh Whether to refresh the StatusSignal before returning it; defaults to true

- Returns

- ClosedLoopSlot Status Signal Object

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ GetConfigurator() [1/2]

|

inline |

◆ GetConfigurator() [2/2]

|

inline |

◆ GetConnectedMotor()

|

overridevirtual |

The type of motor attached to the Talon.

This can be used to determine what motor is attached to the Talon FX. Return will be "Unknown" if firmware is too old or device is not present.

Default Rates:

- CAN 2.0: 4.0 Hz

- CAN FD: 100.0 Hz (TimeSynced with Pro)

This refreshes and returns a cached StatusSignal object.

- Parameters

-

refresh Whether to refresh the StatusSignal before returning it; defaults to true

- Returns

- ConnectedMotor Status Signal Object

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ GetControlMode()

|

overridevirtual |

The active control mode of the motor controller.

Default Rates:

- CAN 2.0: 4.0 Hz

- CAN FD: 100.0 Hz (TimeSynced with Pro)

This refreshes and returns a cached StatusSignal object.

- Parameters

-

refresh Whether to refresh the StatusSignal before returning it; defaults to true

- Returns

- ControlMode Status Signal Object

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ GetDeviceEnable()

|

overridevirtual |

Indicates if device is actuator enabled.

Default Rates:

- CAN 2.0: 4.0 Hz

- CAN FD: 100.0 Hz (TimeSynced with Pro)

This refreshes and returns a cached StatusSignal object.

- Parameters

-

refresh Whether to refresh the StatusSignal before returning it; defaults to true

- Returns

- DeviceEnable Status Signal Object

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ GetDeviceTemp()

|

overridevirtual |

Temperature of device.

This is the temperature that the device measures itself to be at. Similar to Processor Temperature.

- Minimum Value: 0.0

- Maximum Value: 255.0

- Default Value: 0

- Units: ℃

Default Rates:

- CAN 2.0: 4.0 Hz

- CAN FD: 100.0 Hz (TimeSynced with Pro)

This refreshes and returns a cached StatusSignal object.

- Parameters

-

refresh Whether to refresh the StatusSignal before returning it; defaults to true

- Returns

- DeviceTemp Status Signal Object

Implements ctre::phoenix6::hardware::traits::HasTalonSignals.

◆ GetDifferentialAveragePosition()

|

overridevirtual |

Average component of the differential position of device.

- Minimum Value: -16384.0

- Maximum Value: 16383.999755859375

- Default Value: 0

- Units: rotations

Default Rates:

- CAN 2.0: 4.0 Hz

- CAN FD: 100.0 Hz (TimeSynced with Pro)